Scott Harms and Chad Oswald

President & Director of Engineering, MetalQuest

The pandemic was no time for half measures. MetalQuest opened a second shop, then produced 251,995 precision parts in 81 days. The company will attend IMTS looking for digital twins, automation, and other high-performance solutions.

Finding Blue Water in Idaho

Do you have the courage to swim in blue water? To go past the sight of land, strike out alone, and peer down into water so blue you get lost in limitless depths? In the business world, finding blue water means finding market spaces far from competitive feeding frenzies. However, you can't dip a toe in blue water; you have to jump in headfirst.

When you do something like try to navigate your way through a pandemic and an oil sector crash, you can't go halfway,

says Scott Harms, president and founder of MetalQuest, a high-volume manufacturer of precision machined parts.

Looking for market diversification and increased labor access, the company recently opened a second location in Post Falls, Idaho, which is just across the border from Spokane, Washington, for its business-friendly environment, strong economic growth, excellent skilled labor availability, and proximity to new markets in the Pacific Northwest.

We're a very proactive company,” says Harms. “The world changed in 2020. At the time, no one knew what the future was going to be. But we said if ever there was a time to rethink who we are and rebuild our company, you've got to do it when everyone else is indecisive.”

In January 2021, Harms and MetalQuest's leadership team formed a vision and a business plan. MetalQuest's vice president, Scott Volk would lead on-site operations in Nebraska, while Harms, MetalQuest director of engineering Chad Oswald, marketing coordinator and human resource manager Ashley Harms (see separate story on Ashley) and a handful of other Nebraska employees travelled to Post Falls to build the new location. A year later, they're already moving into a larger facility, also in Post Falls. They have 15 employees and plan to add more.

It was a very unique time when we made the decision to start the location,

says Oswald, who has been with the company for 22 years. We really had to look at things like we were a 25-year-old startup, but we also had resources and experiences from our Nebraska operation to support us and make the new location possible.

Experience includes implementing IIoT before the term even existed, helping achieve an OEE in the 90s on more than one of its machines and greater than 80 on another 50% of its machines. A sophisticated ERP system, connected metrology equipped, Zoller presetters, and high degree of automation all differentiate MetalQuest. Against that backdrop, the company shares some of its strategies to replicate its success in Nebraska at the new Idaho facility.

Always Evolving

MetalQuest specialized in making precise components in high volumes. Where many shops have a top-notch machinist that can make amazing one-off parts, few have the company's ability to make complex parts in quantities of 50,000 or more. It requires a unique approach and a willingness to invest in the right equipment.

We built our new operations around the INDEX MS40-8 because it's a factory in itself. It's amazing with all the things it can do,

says Oswald. More than just an eight-spindle turning machine with 40 mm bar stock capacity, the MS40-8 has live tools, C-axis and Y-axis capabilities that give MetalQuest access to such processes and off-center drilling and thread cutting, including drilling, cross drilling, contour milling, hobbing for cutting teeth, and polygon turning.

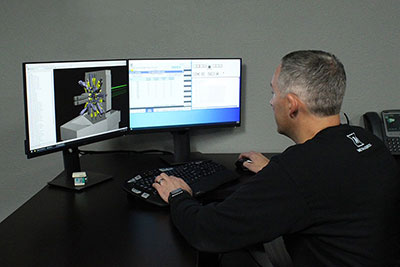

Most importantly, MetalQuest also implemented INDEX's Virtual Machine digital twin software. Virtual Machine enables MetalQuest to confirm actual results for every set-up before the tool ever touches metal and can remove unproductive time related to programming collisions, changeover, training, and quality control. The results are transformative. From June 20 through October 20, the machine made 251,995 complex hydraulic tractor parts, or more than 3,100 parts per day or about 15 seconds per part. About the size of a golf ball, each part has about 70 dimensions.

Oswald notes that the company had the vision to purchase a twin spindle, twin turret multitasking lathe in 1999 when no companies of its size (about 20 people) were doing that. A five-operation part became a one-operation part.

Our thinking puts us in blue water. Basically, the sharks are all in the red water, there's blood in the water and everybody is fighting,

says Oswald. Fast forward 20 years, and our original machines are more commonplace. We had to seek our next evolution and get back into blue water. That's why we looked at the INDEX MS40-8 multispindle machine and got the guts to go for it. That was a real differentiator for us and moved us away from 30,000 competitors to just a few hundred competitors.

A lot of companies say they're a high-tech company. In many instances, that doesn't hold water,”

says Harms. We built our entire team literally thinking out of the box. We look at processes, technology, and people and take actions that help us evolve. IMTS is a huge element of that. It took five IMTS shows for us to be brave enough to make the capital expenditure for the INDEX. We always hit the INDEX booth at IMTS, and we connect with other vendors as well.

(INDEX )

In addition to INDEX, MetalQuest has had a tremendous relationship

with Okuma since its inception, including using its connected technology for machine monitoring. To get things started at the Post Falls facility, the initial equipment list included an Okuma LB3000 EX II lathe and an Okuma Genos M560-V vertical machining center (VMC).

We knew the Okuma M560 was capable of anything that we'd throw at it from a vertical production standpoint,

says Harms. The LB3000 has live tooling, Y axis, and a sub spindle. It's an excellent, versatile job shop-style machine that is kind of like a Swiss army knife for serving our customers.

Oswald notes that when equipping the shop, they wanted to avoid competing with the Nebraska operations, which has twin- and triple-turret systems, mostly from Okuma. That's why one of the new machines added to the Post Falls facility was a Tsugami B0326-III, a six-axis convertible opposed gang tool CNC lathe that adds Y2-Axis capability to enable overlapped, simultaneous machining, as well as back slotting, back-end milling, and back cross drilling/tapping. It offers Swiss turning performance with job shop flexibility and 32 mm bar stock capacity.

We had opportunities on Swiss-style parts and we knew there was a market, but we have not quoted them because we didn't have the capability. Now we can offer a new service to our customers,

says Oswald.

The company also had opportunities in the firearms industries, such as high-end scope mounts and other aluminum products. The Okuma VMC could do the work, but the company's FANUC ROBODRILL α-D21LiB5ADV delivers spindle speeds up to 24,000 RPM, giving it a cycle time advantage – so much so that MetalQuest is looking at a second ROBODRILL after it moves into its new, larger facility.

FANUC plans to launch a digital twin for the ROBODRILL at IMTS, making it a sure destination for MetalQuest.

At IMTS, I'm confident I'm going to find digital twin technology,” says Oswald. “That will be my search, to find out who's got it and how can we leverage it?”

IMTS Strategy

The team from MetalQuest hasn't missed an IMTS show since the company's founding in 1996, at one point sending more than 20 people to the show. Harms' philosophy, reinforced from team feedback, is that costs (whether for attending the show or for equipment) can't be looked at as a singular item; they must be viewed in the context of a bigger picture.

At IMTS, we often focus on solving problems attached to a specific project,” says Harms. “For example, one year we needed to make a relatively simple oil field part but at high volumes. By meeting with FANUC at IMTS, we found an entire toolkit of options that helped us build a highly automated robotic cell, and we met some great people along the way. This year, we have a complex part. I really want to explore out-of-the-box automation solutions from people who do this stuff for a living, and I know I'll find great ideas at IMTS.”

Oswald chimes in, The other thing that IMTS really brings is the opportunity for networking. When you go there, you can't be afraid to ask a question. Many times, you're literally one connection away from the expert on whatever answer you need. If there's best practices, we're really looking for that. Also, teach us what to avoid, which is many times as important as knowing what to do.

MetalQuest has a mission of keeping up with the latest technology, and by way of social media. Marketing coordinator and human resource manager Ashley Harms promotes the company's technology by engaging with as many people as possible on LinkedIn, Facebook, Instagram, and YouTube. MetalQuest employs about 80 people between its Nebraska and Idaho locations, and the company's marketing activities surpass that of companies 10 times its size.